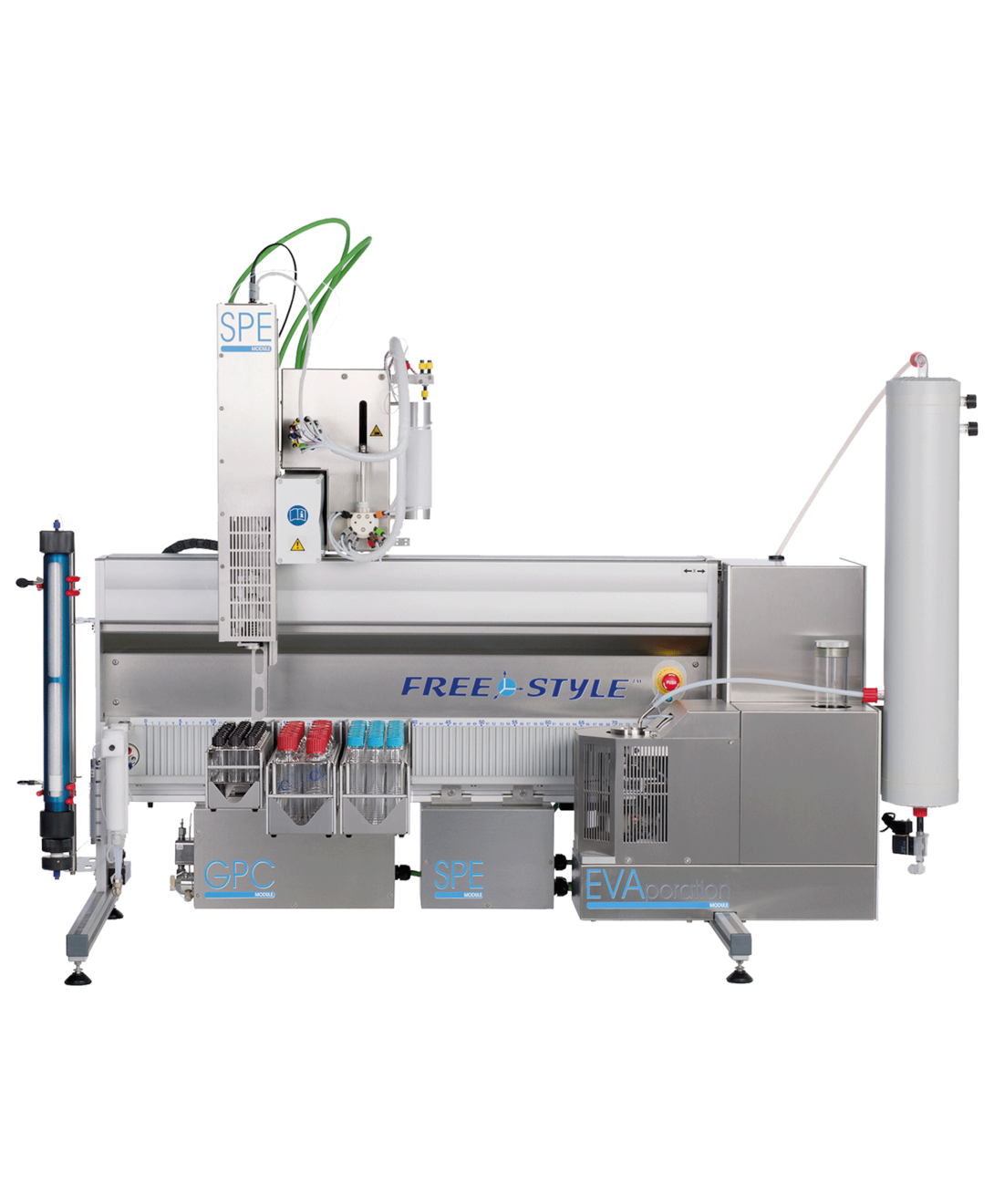

FREESTYLE GPC / SPE / EVA

FLEXIBLE, PRECISE, MODULAR

FREESTYLE GPC / SPE / EVA

Pesticide analysis is an important component, especially in food monitoring, where an enormous number of samples must be analysed for pesticide residues every day. There are various methods that can be used for this purpose, depending on the application. Despite the widespread use of QuEChERS, gel permeation chromatography (GPC) still plays an important role in sample purification, especially in the analysis of fatty matrices such as fish oil, where other methods such as dispersive QuEChERS do not work adequately.

One advantage of GPC is that employees do not need any special expert knowledge. The methodology is established worldwide and can be implemented easily thanks to set regulations such as the expanded revised version of DFG method S19 (L 00.00-34). This facilitates implementation and ensures that the analysis is results-oriented and reliable.

Another pesticide robotics system:

- Home

- Products

- Clean-up with Robotic Systems

- FREESTYLE Pesticides

- FREESTYLE GPC / SPE / EVA

DETAILS AT A GLANCE

FREESTYLE GPC/SPE/EVA

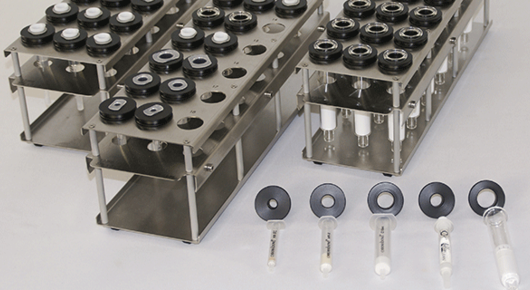

The column is firmly connected to the arm, therefore sample and solvent can be dosed precisely and at a constant flow rate via the SPE column with positive pressure using a syringe pump. Drying is also carried out via positive pressure with nitrogen.

- Non-stop Policy: If a column becomes blocked, the system detects the overpressure. The column is reset, the system cleans itself automatically and continues with the processing of the next column

- One rack for all types of columns: reusable adapters allow easy changing and mixing of columns of any standard format

- Columns can be moved to any position in the rack area

- Three solvents as standard, upgrade option up to six or even fifteen solvents

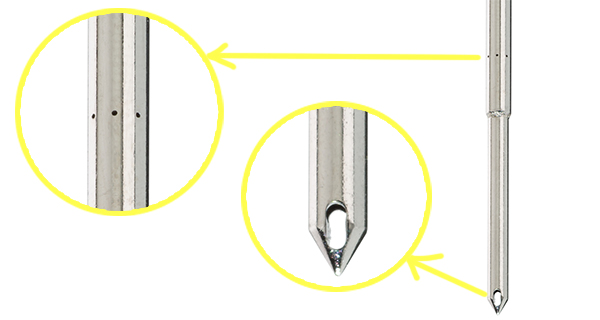

Double-walled with two independent lines inside the needle. Spray holes are arranged 360° around the needle:

- Spraying solvent into a vial (e.g. for quantitative transfer) or into the vacuum chamber for rinsing and/or cleaning

- Filling into vials closed with septa (e.g. 1 mL vial with insert)

- Sharp tip for piercing a septum without punching out parts of the septum

More than 40 different racks (also temperature-controlled) can be freely combined with the FREESTYLE system.

Maximum flexibility for your applications, just as you need it, also for IAC columns. Only one rack type is needed for all columns in standard formats up to 15 mL. Adaptation is done by adapters. The racks are hooked in easily and transferred to the software with just a few mouse clicks.

Fluidics management is a central component of the robotic system, where precise dosing and control of fluids is essential:

- 10 mL syringe pump for an exact way to dispense solutions and samples in defined quantities with defined flow rates

- 6 freely selectable ports for solvent supply. (Optional upgrade for 15 freely selectable solvents possible)

- N2 valve for drying or evaporation process

- Chemically inert PTFE sample loop for cross-contamination-free work

- Tight due to sophisticated design with few sealing elements

- Pressure-stable (tested up to 20 bar continuous operation and 40 bar short-term)

- No cross-contamination in subsequent samples, even with demanding matrices

- DFG S19 compliant (D25)

- Quality certificate and test chromatogram for each column

- Double plunger pump (analytical or preparative pump head possible) for pulsation-free, precise pumping with defined flow rate (parameterisable) Extremely robust design.

- Precise pressure monitoring in the low-pressure range (between 0 - 10 bar).

- Optional high-pressure version up to 100 bar / 1450 psi (with SST injection valve).

- Optional UV detector recording with peak allocation.

The EVAporation module achieves reliable and precise concentration of samples:

- Parameterisable vacuum with controlled heating and rotation of the EVAporation chamber

- Blow-off with nitrogen or air (for sensitive analytes and final volumes < 0.5 mL)

- For each method, any final volume between 0.2 mL and 5.0 mL - in steps of 0.1 mL - is defined via the software and stored in the method

- Methods with different final volumes can be mixed in one sequence - fully automatically and without the use of any tools

- The chamber can be calibrated automatically at the touch of a button

- Incomparable flexibility with regard to the desired final volume from method to method and from sample to sample

- Possibility for automated solvent exchange (liquid/liquid or dry/recovery in desired solvent)

- Overfill sensor for safe handling and monitoring of the process

- Cleaning of the chamber via the sampler needle with rinsing capillary and 360° rinsing/spraying radius for cross-contamination-free work