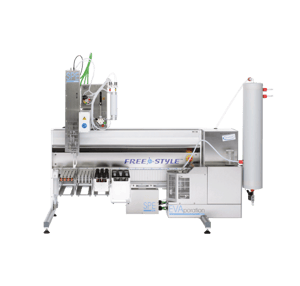

FREESTYLE Forensic

FLEXIBLE, PRECISE, MODULAR

FREESTYLE Forensic

Within forensics and toxicology, there are often samples that are considered difficult to process due to their characteristics. These could be, for instance, especially viscose samples or samples with protein filaments. These often lead to deposits in tubings and valves and ultimately cause blockages. LCTech offers a technically brilliant solution for these particularly difficult samples.

- Home

- Products

- Clean-up with Robotic Systems

- FREESTYLE Forensic

BIDIRECTIONAL SPE

Ingenious Automation

Bidirectional SPE proves to be extremely effective, even with difficult and viscose matrices such as brain tissue or horse or camel urine, which often cause blockages in pipes.

The system uses an SPE module that grips and seals the column to aspirate the sample and prevent contamination of the device. The sample is aspirated via the luer tip and then pushed out again under pressure so that it only comes into contact with the column. This minimises unwanted matrix effects and increases the precision and reproducibility of the analysis.

Examples of Applications Bidirectional SPE

Used in the Daily Routine

Determination of drugs in human brain

Determination of drugs in human blood

High-throughput determination of drugs in horse or camel urine in doping control

FREESTYLE Piles on the Pressure!

Positive pressure of up to 4 bar can be used in the FREESTYLE system, which pushes these difficult-to-process samples through the column in a controlled manner. If a column should nevertheless become blocked, the adjustable pressure monitoring system ensures that the system stops processing this sample, marks the sample in the sample list, cleans itself and begins processing the next sample in the sample sequence. This guarantees the continuous processing of a sequence, which takes a great deal of pressure off your laboratory. This non-stop policy enables unattended sample processing overnight or over the weekend.

Increase Flow Rates

The additional use of plungers means that dead volumes in the columns can be minimised and flow rates increased. Conditioning, washing and elution solutions are thus applied to the column at constant pressure, the processing time for the sample is shortened.

Advantages of the FREESTYLE

Proven: No Cross-contamination!

Carryover is reliably eliminated thanks to a sophisticated system design, specially selected components, such as valves and needles, integrated rinsing steps and unique sample loading processes.

Processing around the Clock

Non-stop policy due to continuous pressure monitoring.

Reliable, Reproducible Results

Automation enables the continuous and precise processing of samples with repeatably identical parameters (e.g. flow rate).

Fast Sample Processing

Depending on the matrix, positive pressure of up to 4 bar can be used. Higher flow rates thus lead to shorter processing times.

Easy to Use

Manual, validated methods can be very quickly transferred to the system with the help of the easy-to-use software. Using drag & drop or slide control, the method parameters are easy to adjust, allowing the individual steps from the manual method to be adopted in automated processing. Saved methods can be accessed and used again in the laboratory routine.

Urgent samples can also be prioritised at any time, even during ongoing operations.

Documentation of Sample Processing

Traceability of the processed samples and the detailed methods via the report function.

The Perfect Sample Loading!

Sample volume: 5 mL

Ideal for forensic matrices, such as e.g. postmortem blood, urine, and highly viscose and particularly adhesive matrices such as brain. The sample is aspirated via the tip of the SPE column. It passes through the column’s sorbent and, immediately afterwards, is discarded in the waste in the opposite direction, where the sample flows through the sorbent a second time.

Ideal sample loading for forensic applications:

- No cross-contamination as sample does not come into contact with the system at any time

- Sample is available for additional analyses

- Elution with minimal amounts of solvents

- Minimises unwanted matrix effects

Sample volume: 0.3 – 1 mL e.g. for small sample volumes.

The sample is aspirated by the sample needle and released directly into the SPE column again.

Sample volume: 1 - 100 mL e. g. for blood and urine samples, horse and camel urine samples.

The sample is aspirated by the sample needle into the chemically inert, easy-to-clean sample loop and, from there, released into the SPE column via the valve.

Dual SPE

In the Daily Routine

Automated processing of two solid phase extractions with different column formats one after the other in one method without manual intermediate steps.

You can read more details about this in the following article in Laborpraxis.

Read more (german)

Determination of steroids in animal food