FREESTYLE SPE

AUTOMATED SOLID PHASE EXTRACTION

FREESTYLE SPE

The manual processing of samples in many laboratories often takes up a great deal of the laboratory staff’s time. This is true both for solid phase extraction and for subsequent concentration (evaporation). Reproducibility is impaired by the many manual steps, such as the manual rinsing of the loading containers or the use of a rotary evaporator. This can lead to inaccurate or inconsistent results and undermine trust in the methods. Automation of these processes can provide assistance here and helps to improve the efficiency and reproducibility of the methods.

- Home

- Products

- Clean-up with Robotic Systems

- FREESTYLE SPE

DETAILS AT A GLANCE

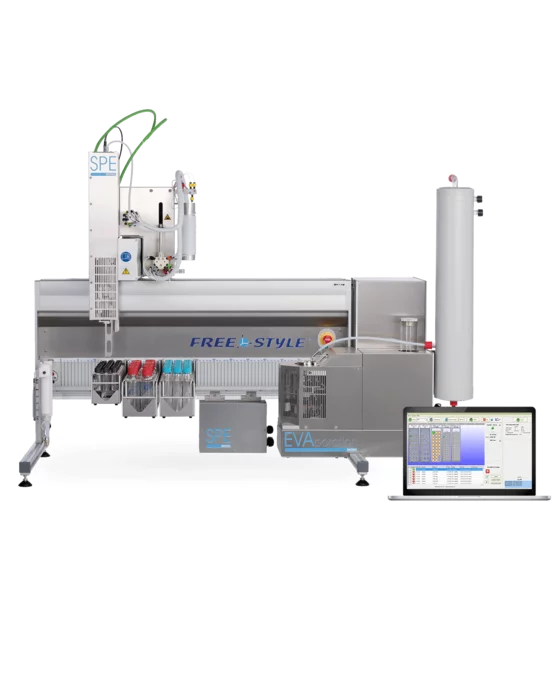

SPE (Solid Phase Extraction)

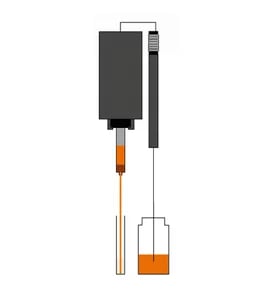

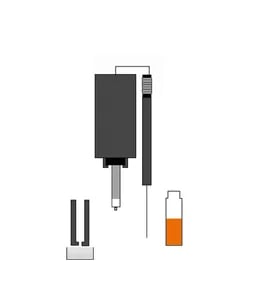

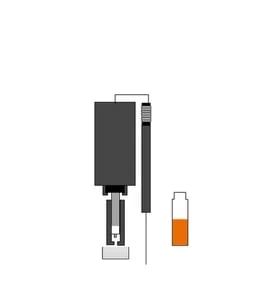

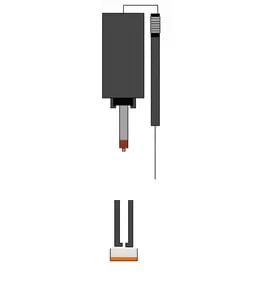

The column is firmly connected to the arm, therefore sample and solvent can be dosed precisely and at a constant flow rate via the SPE column with positive pressure using a syringe pump. Drying is also carried out via positive pressure with nitrogen.

- Non-stop Policy: If a column becomes blocked, the system detects the overpressure. The column is reset, the system cleans itself automatically and continues with the processing of the next column

- One rack for all types of columns: reusable adapters allow easy changing and mixing of columns of any standard format

- Columns can be moved to any position in the rack area

- Three solvents as standard, upgrade option up to six or even fifteen solvents

.webp)

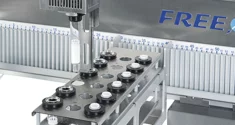

Double-walled with two independent lines inside the needle. Spray holes are arranged 360° around the needle:

- Spraying solvent into a vial (e.g. for quantitative transfer) or into the vacuum chamber for rinsing and/or cleaning

- Filling into vials closed with septa (e.g. 1 mL vial with insert)

- Sharp tip for piercing a septum without punching out parts of the septum

.webp)

In the washing device, the double-walled needle is cleaned from the inside and outside. This further ensures cross-contamination-free working.

More than 40 different racks (also temperature-controlled) can be freely combined with the FREESTYLE system.

Maximum flexibility for your applications, just as you need it, also for IAC columns. Only one rack type is needed for all columns in standard formats up to 15 mL. Adaptation is done by adapters. The racks are hooked in easily and transferred to the software with just a few mouse clicks.

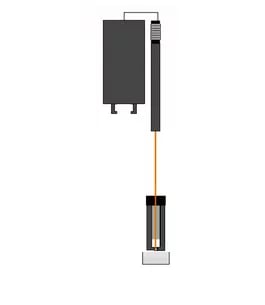

A direct, automated elution of the SPE column, directly into the EVAporation chamber within one method (online), is particularly convenient. An optional liquid/liquid solvent exchange completes the automation.

For more details on the advantages of the EVA module, please refer to the corresponding product page.

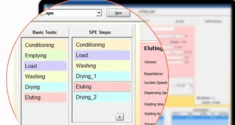

FREESTYLE EVAporationSPE method: The software enables the transfer of almost any manual method directly into automation.

- Simple operation through drag & drop

- Dual SPE: Two solid phase extractions can be automated in one method

Applications for Special

Areas of Use

Excessively high blank values and thus incorrect results are a well-known challenge when analysing perfluoroalkyl and polyfluoroalkyl substances (PFAS). These are created from the material used in clean-up and measurement systems, as the plastics containing fluorine that are often used can release PFAS.

In the PFAS version, all of the components (tubings, valves, etc.) in the fluidic path are PTFE-free!

Read more

While humans dislike doing the same thing over and over again, it is one of the most striking characteristics of the FREESTYLE. Even the most lengthy applications in mycotoxin analysis are processed accurately and diligently, day and night.

Read more

Suspended particles in water can easily clog or block the surface of a SPE column. In many instances, even samples with suspended particles can be pushed through the SPE columns in a controlled manner using 4 bar of positive pressure. The type of elution can be chosen freely. Larger sample volumes from 1 L to 10 L can easily be automated with the robotic system for water analysis, FREESTYLE XANA.

Read moreAdditional Application Examples

QuEChERS Pesticide Analysis

QuEChERS à la LCTech is based on a non-dispersive clean-up step and has specially adapted columns. This covers almost all matrices within pesticide analysis in food and feed. The non-dispersive application with the columns saves time (no shaking, no centrifugation) and leads to better chromatography due to the high clean-up and the reduced matrix ion suppression associated with this. This is reflected in very good recovery rates with high reproducibility.

Steroids in Animal Feed

By modifying the FREESTYLE software, two solid phase extractions (“Dual-SPE”) with different column formats can be processed automatically one after the other. Specially developed plungers minimise the dead volume, increase flow rates and thus reduce the processing time per sample.

H53 Method

In combination with the EVAporations module, the FREESTYLE SPE takes over the complete clean-up for the analysis of petroleum hydrocarbons: Extraction, concentration to 1 mL and filling of the finished sample into a GC vial. Of course, the processes can also be carried out separately. For the clean-up step, we recommend the cost-effective Florisil Elufix™ columns.

Forensic / Toxicology

The sample loading procedure for bidirectional SPE (solid phase extraction) enables even difficult matrices, such as brain tissue or similar matrices, to be processed automatically without supervision 24 hours a day, 7 days a week. Cross-contamination can thus be eliminated due to the nature of the procedure.

High Throughput in Doping Testing

Urine samples from racehorses/camels are particularly difficult to process due to their viscosity, as this may cause a blockage in a column. A pressure check alone is not enough in such cases. The FREESTYLE software has an excellent solution: if a column becomes blocked, the processing of this sample is terminated, the sample is marked in the sequence list and the next sample is processed! Such features realise end-to-end automation without downtime.

FROM A LABORATORY FOR ENVIRONMENTAL TESTING

"The application of LCTech

micro-SPE Pesticide I, Pesticide II and Pesticide III cartridges has revolutionised our sample clean-up.”

Flexible Sample Loading

The various types of sample loading open up many different possible application: from large volumes of up to approx. 100 mL in mycotoxin analysis down to just a few µL, such as in forensics.

The FREESTYLE technology offers the right solution for any application, which can simply be selected in the software when setting up the method.

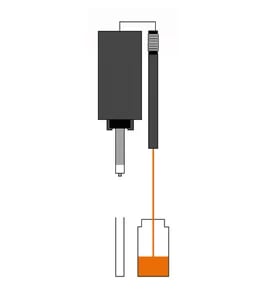

Sample loading of large-volume samples

These samples (up to approx. 100 mL) are ideally aspirated into the sample loop (possibly several times) via the needle (first Z axis) and then released onto the SPE column (second Z axis).

Aspirate into sample loop

Release into the SPE column

Discharge into waste or collect in a container

Ready for further process steps

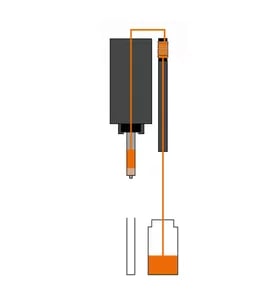

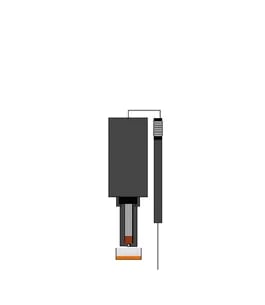

Loading of small-volume samples (e.g. 500 µL)

The column is conditioned and positioned in the wash port. The small sample volume (e.g. 500 µL) is directly pipetted into the column using the needle. The SPE unit then takes up the column again and the process continues.

Gripper picks up the SPE column

Positions it in the wash port

Aspiration of the sample from the sample container

Release into the SPE column

Release into waste

Gripper picks up the column again: ready for further process steps

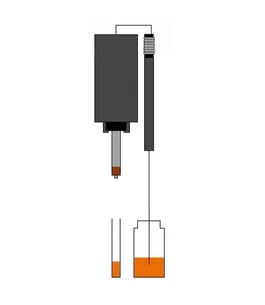

Flexible Elution

Elution from the SPE column can be performed in many ways. Even highly complex elution processes can be carried out. The different procedures are saved as a macro in the software and can easily be integrated into a method. A selection of different racks enables elution into different containers, e.g. into a 2 mL or 5 mL graduated flask, if a defined final volume is needed.

Standard Procedures

Elution with one solvent into one container.

Elution with several solvents into different containers.

Special Procedures

Elution with one solvent into several containers of the same size (up to 10 containers). Each vial is filled to its maximum before the next vial is filled.

Elution with several solvents into one container.

PRODUCT VIDEOS + WEBINARS

Videos

Fast and Easy SPE-Method Transfer on Automated Clean-up System

Automated Solid Phase Extraction

.webp)

Residues and Contaminant Analysis - One Sample Preparation Solution

.webp)

Introduction to LCTech`s FREESTYLE EVA for automated EVAporation

.webp)

Introduction to LCTech`s FREESTYLE SPE for automated Sample Preparation