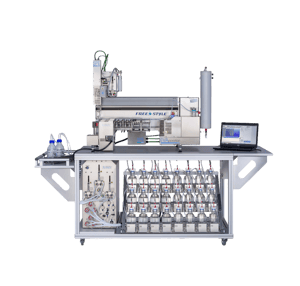

FREESTYLE XANA PFAS TableTop

FLEXIBLE, PRECISE, MODULAR

FREESTYLE XANA PFAS TableTop

The FREESTYLE XANA PFAS TableTop is well-prepared for the requirements relating to PFAS. The analytical challenges are overcome by replacing all PTFE-containing components with blank value-free materials, such as PE and PP. This enables method-compliant sample processing according to US EPA standards (e.g. 537.1, 533, 1633) and DIN 38407-42 without producing blank values.

Large volumes are not absolutely necessary in order to analyse PFAS in water. As a result, the large bottle rack of the XANA is not needed in some cases. By downscaling the bottle rack, it can now be easily transferred to the FREESTYLE, saving a huge amount of space.

More PFAS Robotic Systems:

- Home

- Products

- Clean-up with Robotic Systems

- FREESTYLE PFAS

- FREESTYLE XANA PFAS TableTop

Specifications

Max. Volume per sample

up to 250 mL

Samples per sequence

30

Duration per sequence

approx. 8 - 9 hours (for US EPA 537.1)

Samples simultaneously

up to 6

Location

on the laboratory bench

Fume hood

not required

PFAS compatibility

PE tubings, PTFE-free syringe, PTFE-free valves

Solvent compatibility

all necessary solvents according to the regulations are compatible

DETAILS AT A GLANCE

XANA PFAS TableTop

The column is firmly connected to the arm, so positive pressure from the syringe pump can be used to press sample and solvent over the SPE column in a very precise and controlled manner. Drying is also done by positive pressure via nitrogen.

- Non-stop policy: If a column is blocked, the system detects this and sends a message to the software. The sample is marked in the event list, the column is reset, contaminated lines are flushed and the system automatically processes the next sample.

- Columns can be moved to any position in the robot area.

- Three solvents as standard, upgrade option to up to six or even fifteen solvents.

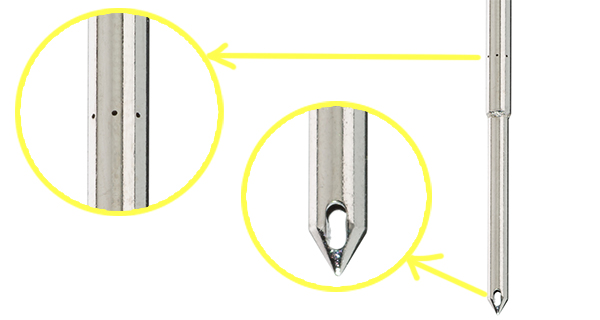

Double-walled needle with two independent lines. For the outer line, spray holes are arranged 360° around the needle. Ideal for thorough all-round cleaning of a vessel.

- Spraying solvent into sample bottles or for rinsing and cleaning

The external processing station is responsible for the fluidics management of the water module with the pumping mechanics of up to 10 L samples, the valves and the sensor technology for process monitoring.

All components in the fluidic way ( tubes, valves, ...) are PTFE-free!

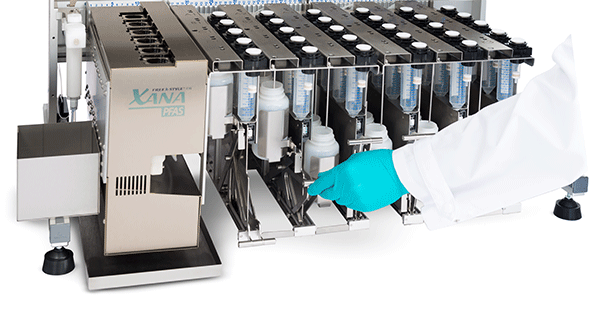

In the processing station on the FREESTYLE platform, 3 SPE columns are processed simultaneously in 2 blocks: In block 1, 3 columns are conditioned, loaded and washed in parallel, while in the following block 2, 3 columns are dried in parallel.

The following videos show the processing station of the FREESTYLE XANA. They are identical for all XANA models:

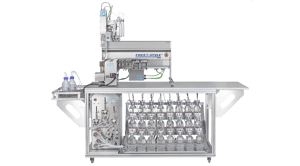

Thanks to its compact design, the XANA PFAS TableTop fits on a single laboratory bench. This allows you to organise your laboratory more effectively and efficiently and save valuable space and resources.

The robotic system works precisely and reliably, so you can even leave it running overnight to further optimise your workflow. It can be equipped with 2 sample racks, each offering 15 positions. This allows you to process up to 30 samples in a single sequence, saving a lot of time and effort.

With bottles for up to 250 mL sample volume, the Robotic System is perfectly suited for e.g. US EPA 537.1, 533 or 1633.

STANDARD-COMPLIANT

Sophisticated Features

Via a special mechanism, Falcon tubes are also transferred into the processing station as eluate containers. This enables the elution solvent to be transferred efficiently and in a standard-compliant manner from the sample bottle into the Falcon tube via the SPE column.

Assignment of LCTech Systems and Columns to the Official Standards

DOWNLOADS

More Info about

FREESTYLE XANA PFAS Table Top

SYSTEM OVERVIEW

Other Solutions for PFAS Applications

LCTech developed robotic systems, specially for the sensitive PFAS application, almost completely free of plastics containing fluorine such as PTFE and thus offers a solution to the problem. It has not been possible to determine any blank values that come from the system.

Alongside large-volume water samples, the PFAS system is also offered for samples from solid phase extraction with smaller volumes (without the XANA module).

The SPE module can be used for all methods in the field of solid phase extraction. Through the controlled application of up to 4 bars of pressure, viscose samples or samples that do not contain solid suspended particles can also be pushed through the SPE column.

With the FREESTYLE XANA PFAS, the automated clean-up of perfluoroalkyl and polyfluoroalkyl substances from up to twenty-four water samples from 0.05 to 10 litres is possible quickly and without supervision, even at the weekend or overnight.

A high sample throughput per day is achieved thanks to the parallel performance of the individual process steps “conditioning”, “loading” and “washing” and the simultaneous processing of 3 samples each.