FREESTYLE CrossTOX®

FLEXIBLE, PRECISE, MODULAR

FREESTYLE CrossTOX®

Mycotoxins are harmful to health and are present around the world. In order to be able to put food or feed into circulation safely, defined limits must be constantly monitored, which requires a reliable analysis as well as reliable sample preparation. Many foods and feeds are contaminated with more than just one mycotoxin, which makes a multi-mycotoxin screening necessary. A simple, fast procedure can be carried out reproducibly and reliably using automated sample processing: matrix reduction, thanks to the CrossTOX technology, is achieved through non-dispersive SPE, whereby effective clean-up is guaranteed and can be carried out around the clock.

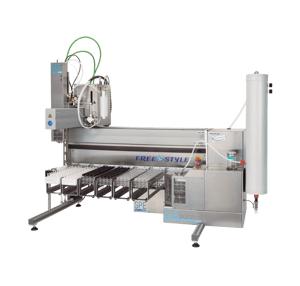

The FREESTYLE for CrossTOX® offers a quickly automated, reproducible and robust method for sample preparation for multi-mycotoxin analysis, which can run without supervision around the clock and thus makes everyday work much easier. The FREESTYLE system offers two possibilities for the automated processing of CrossTOX® columns:

- from the raw extract to the cleaned-up sample or

- from the raw extract to the chromatogram with HPLC Direct Injection

More Mycotoxin Robotic Systems:

- Home

- Products

- Clean-up with Robotic Systems

- FREESTYLE Mycotoxins

- FREESTYLE CrossTOX®

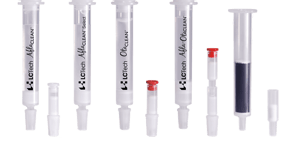

CrossTOX® – 18 Mycotoxins in One Go!

The CrossTOX® column enables the optimal separation of matrix interferences and interfering substances due to its non-dispersive SPE material in order to pass the analytes on to be measured via LC-MS/MS.

Toxins investigated to date

Aflatoxins B1, B2, G1, G2, sterigmatocystin, ochratoxin A, fumonisin B1 and B2, deoxynivalenol, nivalenol, 15-acetyl DON, 3-acetyl DON, DON-3-GLC, zearalenone, T-2 and HT-2, citrinin, diacetoxyscirpenol

DETAILS

FREESTYLE SPE / Direct Injection in LC-MS/MS

The column is firmly connected to the arm, therefore sample and solvent can be dosed precisely and at a constant flow rate via the SPE column with positive pressure using a syringe pump. Drying is also carried out via positive pressure with nitrogen.

- Non-stop Policy: If a column becomes blocked, the system detects the overpressure. The column is reset, the system cleans itself automatically and continues with the processing of the next column

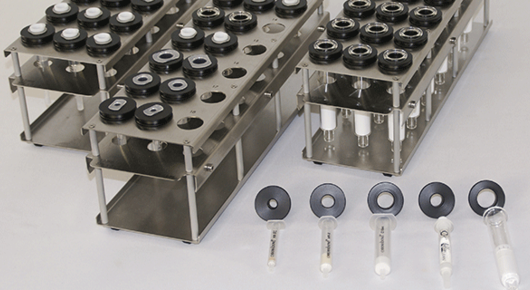

- One rack for all types of columns: reusable adapters allow easy changing and mixing of columns of any standard format

- Columns can be moved to any position in the rack area

- Three solvents as standard, upgrade option up to six or even fifteen solvents

.jpg)

Fluidics management is a central component of the robotic system, where precise dosing and control of fluids is essential:

- 10 mL syringe pump for an exact way to dispense solutions and samples in defined quantities with defined flow rates

- 6 freely selectable ports for solvent supply. (Optional upgrade for 15 freely selectable solvents possible)

- N2 valve for drying or evaporation process

- Chemically inert PTFE sample loop for cross-contamination-free work

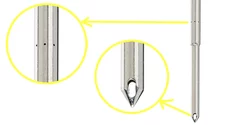

Double-walled with two independent lines inside the needle. Spray holes are arranged 360° around the needle:

- Spraying solvent into a vial (e.g. for quantitative transfer) or into the vacuum chamber for rinsing and/or cleaning

- Filling into vials closed with septa (e.g. 1 mL vial with insert)

- Sharp tip for piercing a septum without punching out parts of the septum

More than 40 different racks (also temperature-controlled) can be freely combined with the FREESTYLE system.

Maximum flexibility for your applications, just as you need it, also for IAC columns. Only one rack type is needed for all columns in standard formats up to 15 mL. Adaptation is done by adapters. The racks are hooked in easily and transferred to the software with just a few mouse clicks.

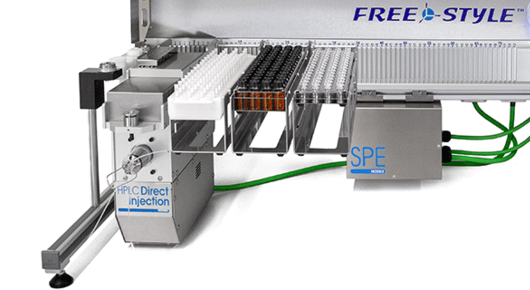

The HPLC Direct Injection module is part of the FREESTYLE automated sample preparation system. It allows complete automation from crude extract to chromatogram without any manual intermediate step with excellent results at the same time, by means of online injection into any LC system. Finished samples can be injected into the HPLC by means of sample loop overfilling, whereby the injection volume can be parameterised.

- Complete automation of a routine analytical process

- Processing of sample and standard without manual intermediate step

- Compatible with any HPLC system

- The FREESTYLE system takes over the function of an autosampler - no HPLC autosampler required

- Filling of additional aliquots of sample possible

- 10 coolable positions for standards available (1 mL or 4 mL vials)

- SST sample loops in different sizes possible

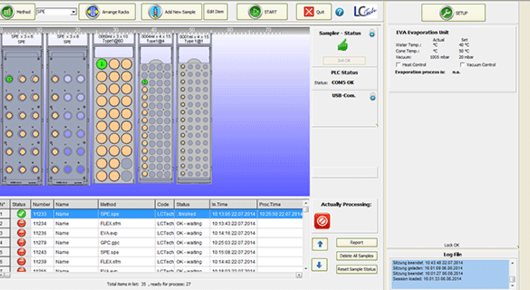

Detailed and varied method creation and easy handling in routine are a successful balancing act in the FREESTYLE software.

- One user interface for all FREESTYLE modules.

- Expandability with new modules at the click of a mouse.

- Easy handling through drag & drop.

- Easy creation, reuse and modification of methods.

- Different methods can be mixed in a sequence list.

- Prioritisation of samples possible at any time, even during operation.

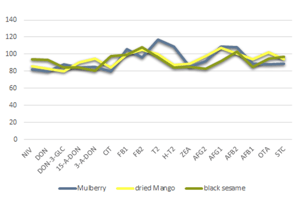

WIDE RANGE OF ANALYTES IN DIFFERENT MATRICES

Excellent Recovery Rates

- Standard was set to 100%

- Experience reliable and reproducible full automation of sample preparation for high-throughput sample analysis.

- Ideal for a variety of matrix groups, such as cereals, nuts, dried fruit and animal feed.

- LCTech’s solution fulfils the regulatory requirements for the mycotoxin analysis of food and feed so that you can rely on the quality and safety of your products

Recovery Rates

Advantages of CrossTOX® Clean-up

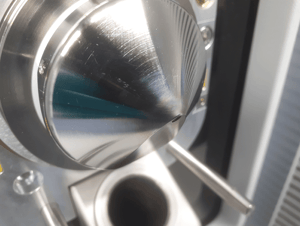

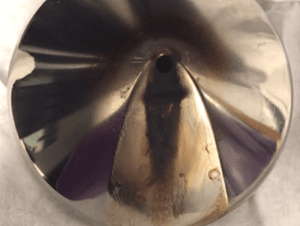

Heated electrospray source following the injection of 1145 samples

- No residues and no interference

- System can continue to run

- Higher analytical drift, lower reproducibility, reduced sensitivity

- System must be maintained – downtime at least 1 day

Get to know the quality of sample clean-up with the CrossTOX® column for mycotoxin analysis. Sample clean-up is an important point in order to reduce matrix interference. In addition, the analysis device is kept at the sensitivity level required for optimal and reliable analysis.

SYSTEM COMPARISON AND ACCESSOIRES

Mycotoxin Robotic Systems

.png?width=300&name=5.4-FREESTYLE-SPE-PFAS@2x%20(1).png)

Unique: thermal denaturation. Full automation from the extract to the chromatogram in less than 20 minutes.

Read more

.png?width=300&name=5.4-FREESTYLE-SPE-PFAS@2x%20(1).png)

- Robust, reproducible, flexible

- Maximum measurement sensitivity with measurements far below the regulated limits

- Can be combined with any HPLC-FLD or LC-MS/MS system

Find out here about highly-selective immunoaffinity columns (IAC), specific SPE columns or the unique CrossTOX® as a multi-toxin column from LCTech.

Read more