DEXTech Heat

DIOXIN / PCB ANALYSIS

Automation for Curing Samples

DEXTech Heat is the solution for difficult samples in dioxin, furan and PCB analysis. In addition to "normal" samples, the DEXTech Heat is ideal for samples that harden at room temperature. These can be reliably kept liquid by the special zone heating technology, automated and cleaned up unattended. These include samples such as palm fats, stearin and PFAD.

The exceptional technology makes it possible: no carry-over, no cross-contamination and no clogging of the column. Simply place the sample in the system, click in the columns and start the process.

The DEXTech Heat, like all DEXTech systems, can be used for a wide variety of methods. The default methods comply with all current standards such as US-EPA 8282B, US-EPA 1613, US-EPA 1668c, EU commission regulation (EC) No 589/214, No 1881/2006, No 152/2009, No 2002/32, GOST 34449-2018 and others.

More DEXTech systems, recommended columns and QS column certificates:

- Home

- Products

- PCDD/F, PCB and other POPs

- DEXTech Product Family

- DEXTech Heat

The system for daily work in the dioxin laboratory and also for particularly difficult samples!

DEXTech Heat

CHALLENGE

Hardening Samples

Samples, such as PFADs or stearin, harden at room temperature. The DEXTech Heat has been developed especially for these samples.

Your sample remains fluid throughout the clean-up process without additional manual handling, as the system heats it at all necessary positions. An automated "walk-away" solution with the certainty that your sample will be reliably processed without clogging. Of course, all other samples can also be processed.

DETAILS AT A GLANCE

Robust and Accessible Technology

The sample is loaded quantitatively into the system via the needle. The receiver vessel is heated and thus prevents the sample from cooling down and possibly hardening. The sample is rinsed several times (quantitative transfer). The needle is cleaned inside and out during the rinsing processes to prevent contamination.

The sample is also kept warm and thus liquid in the sample loop. Thus, it continuously warms the solvents and thus also the silica column (first column during sample introduction).

In addition, the sample loop has the same functionality as the DEXTech Pure to add the sample focused onto the silica column at the same time as the cleaning solution of the automated sample transfer. It is continuously flushed with fresh reagent and has been proven to remain contamination-free. By using a sample loop, the sample does not come into contact with either the syringe pump or the piston pump, which enables rapid cleaning of the system.

The columns are clipped into the column tower in a few seconds. After pressing the start button, they are pressed together pressure-tight and the process is started. For your protection, the columns can only be pressed together when the door is closed. You can find the matching clean-up columns here.

The syringe pump is used to load the sample onto the column. The sample does not come into contact with the pump, so that it always remains contamination-free.

The special technique for difficult samples

The DEXTech Heat is similar to the DEXTech Pure, but has the special heating to keep curing samples liquid.

The following are heated: the sample feed, the sample loop and all tubing through which the sample flows. Due to the reactions on the silica column (first column during sample loading), this becomes warm during the process and does not require additional heating. The heating can be adjusted in a zone-controlled manner.

All tubing connections are permanently installed and do not need to be conditioned or replaced for each sample.

Via the touch display the user is guided through an intuitive operating program to start recommended and tested default methods for different approaches (e.g. dioxins and PCB or PCB only etc.) around methods stored in the system. Method development by the user is not required, yet programming of own methods remains possible.

INDIVIDUAL AND FLEXIBLE

Fractionation on All

DEXTech Systems

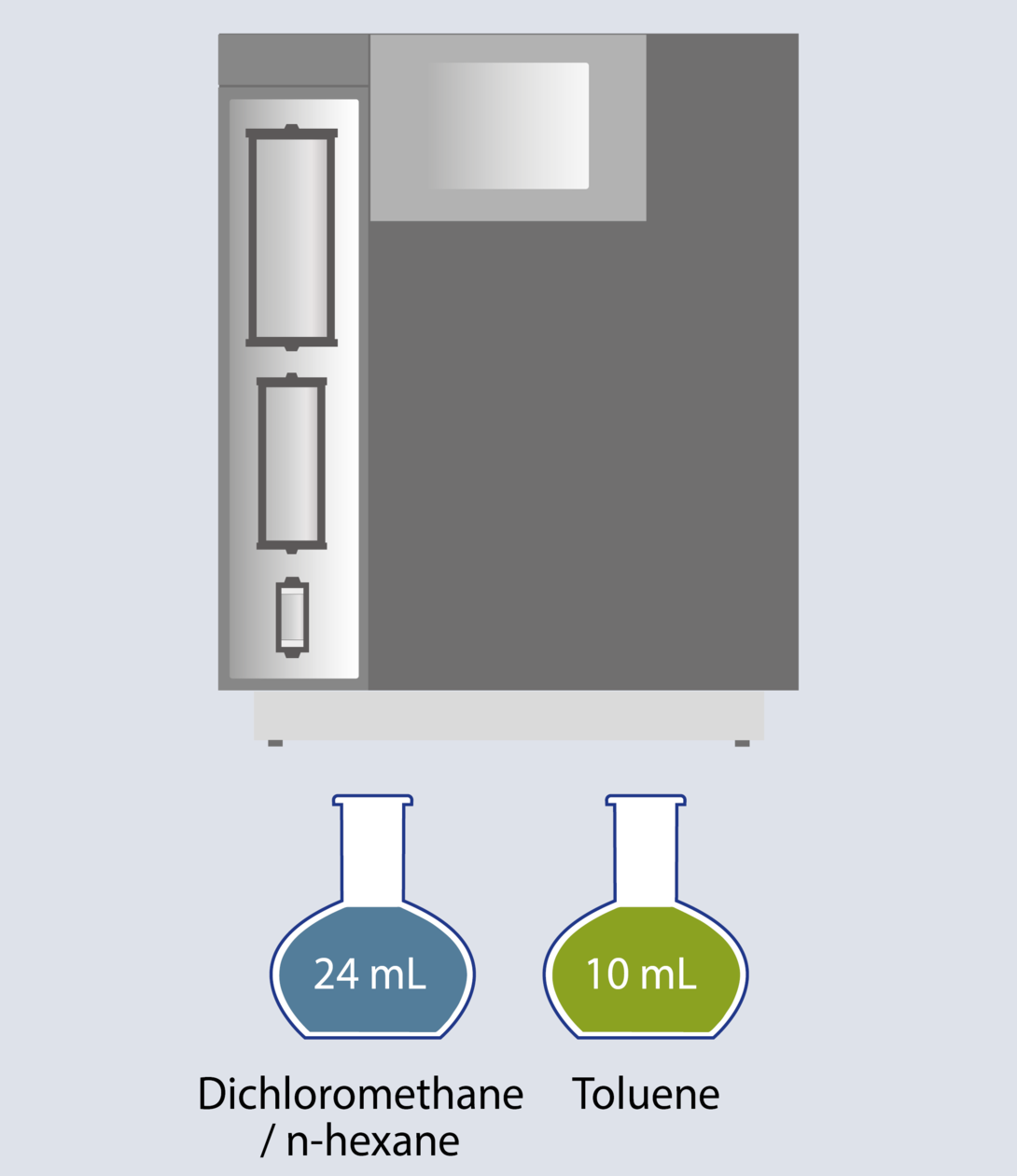

3 Columns

2 Fractions

Fraction 1 (24 mL):

Mono-ortho-PCB + ndl-PCB + PBDE

Fraction 2 (10 mL):

Non-ortho-PCB + PCDD/F + PCNs

Total process time: 65 min

Total process time SMART: 45 min

Also available as DCM Free Method

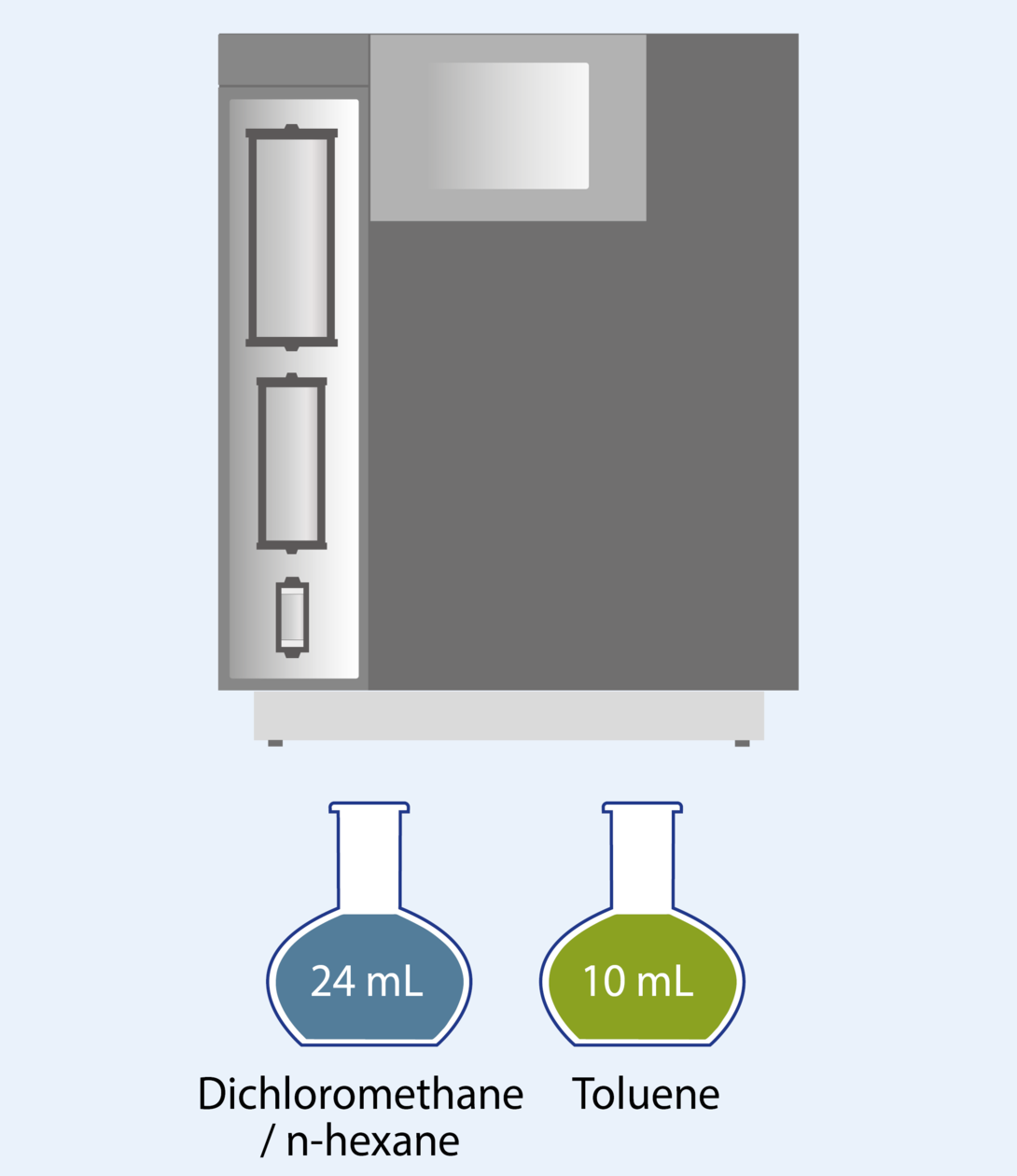

3 Columns

2 Fractions

Fraction 1 (24 mL):

Mono-ortho-PCB + ndl-PCB + Non-ortho-PCB

Fraction 2 (10 mL):

PCDD/F

PCNs

Total process time: 72 min

Total process time SMART: 52 min

Unique: All PCBs in one fraction

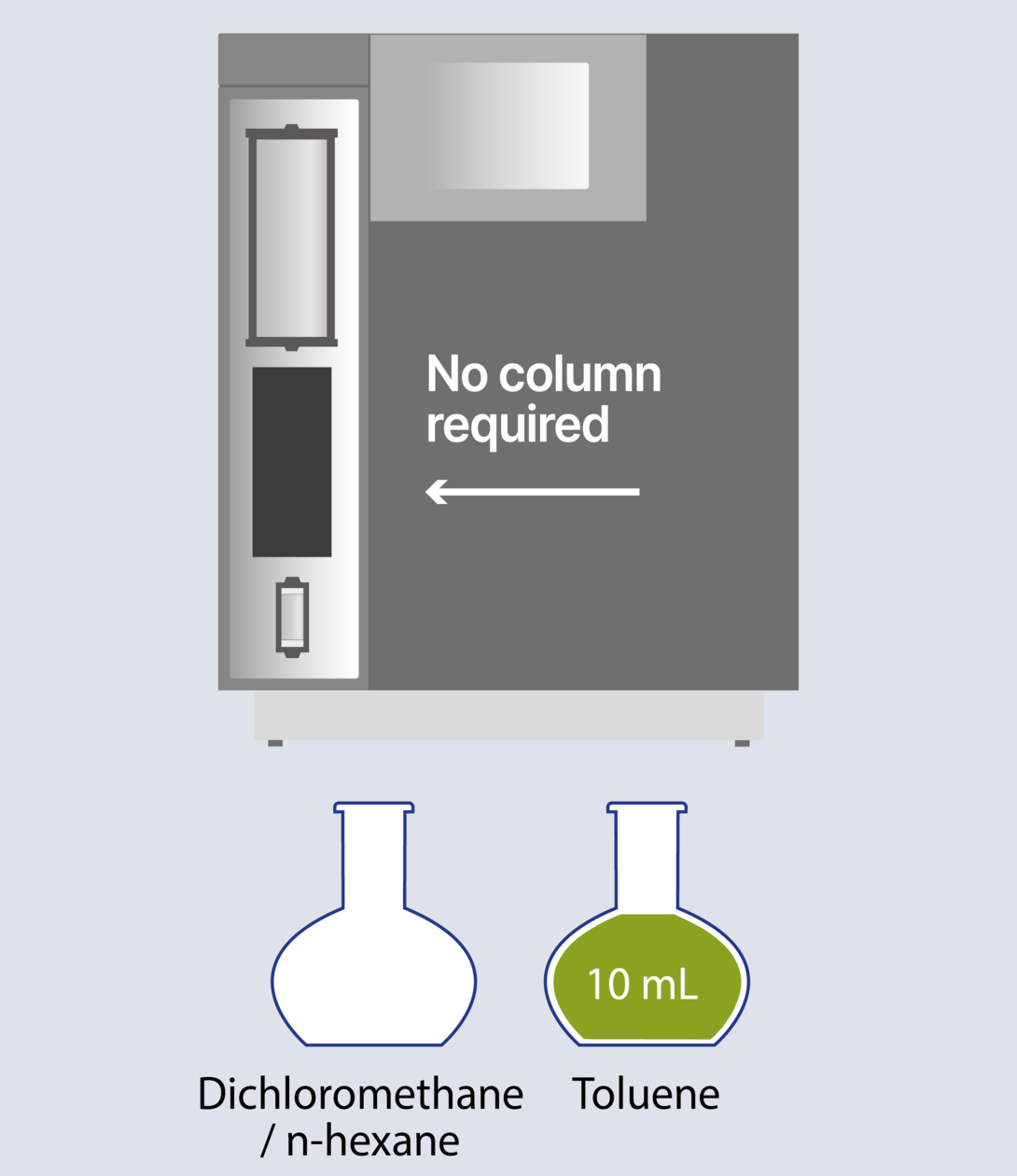

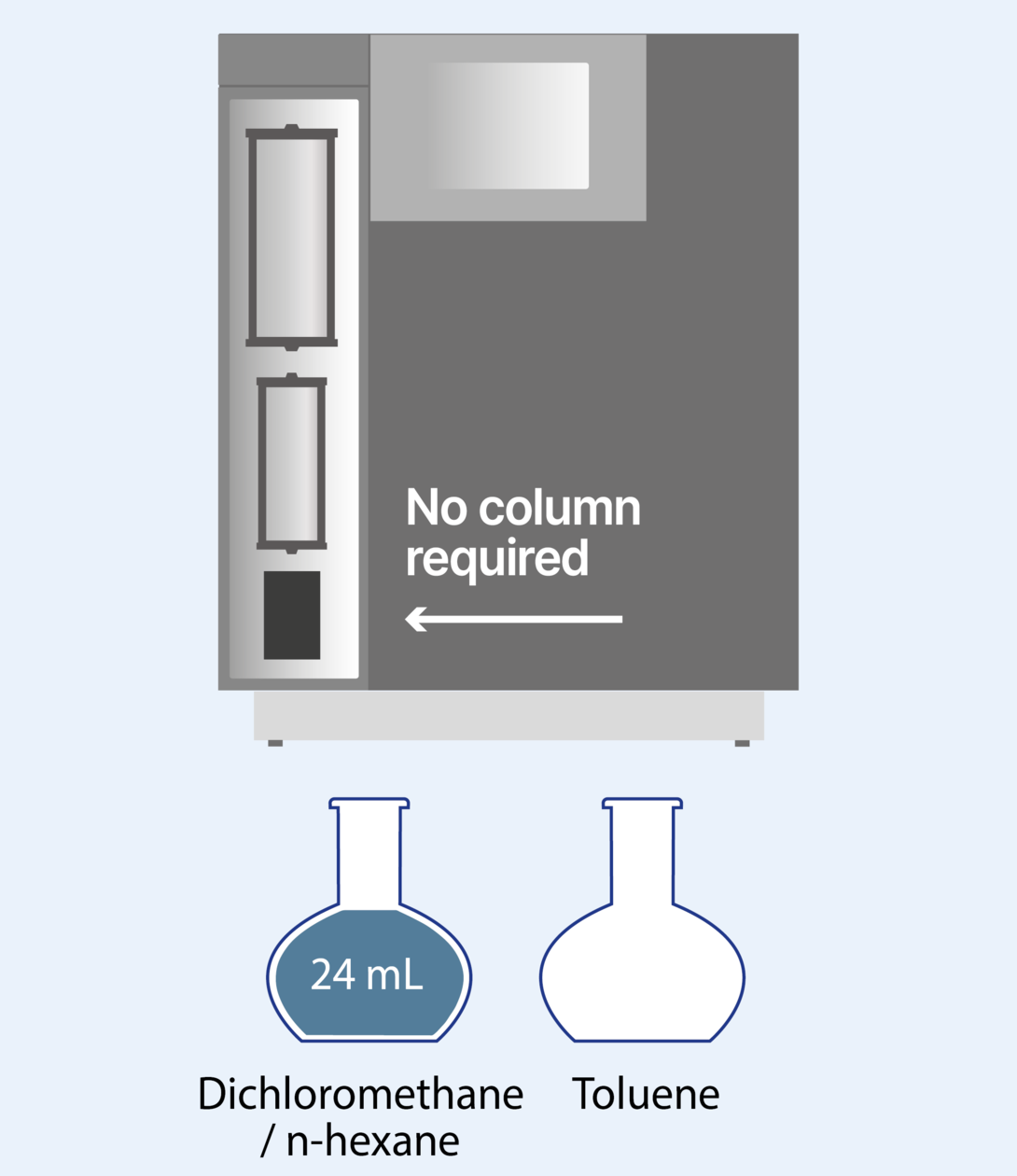

2 Columns

1 Fraction

Fraction 1 (24 mL):

-

Fraction 2 (10 mL):

PCDD/F

PCNs

Total process time: 52 min

Total process time: SMART: 32 min

Cost saving and DCM Free Method!

- PCB only (Mono-ortho-PCB, + ndl-PCB, + non-ortho-PCB)

- PCB 209 (All 209 PCBx)

2 Columns

1 Fraction

Fraction 1 (24 mL):

PCB only

(Mono-ortho-PCB,

+ ndl-PCB,+ non-ortho-PCB)

Total process time: 54 min

Total process time SMART: 34 min

Fraction 1 (24 mL):

PCB 209 (All 209 PCBs)

Total process time: 33 min

FOR PCB AND DIOXIN SAMPLES HARDENING AT ROOM TEMPERATURE

Best Results by Heating

DEXTech Heat reliably processes all samples from PCB and dioxin analysis. The heating prevents clogging of the clean-up column. In addition, the samples obtain a homogeneous consistency, resulting in a better distribution of the quantification standard and thus better recoveries.While fractionating a sample, it is already possible to heat the next sample offline. This saves additional time.

PRODUCT VIDEOS + WEBINARS

Videos

OVERVIEW

More DEXTech Systems and Recommended Columns

The basic system for daily routine. Proven hundreds of times in laboratories around the world.

Read more

The automated system for 15 samples in one sequence. Fully automated also overnight!

Read more

Silica columns and Alox columns made of glass or plastic. You have the choice!

Read more