DEXTech 16

DIOXIN / PCB ANALYSIS

15 Samples in One Sequence!

The DEXTech 16 is the world's only system for sequential and unattended processing of 15 samples. A typical "walk-away" system: set up the samples, click in the columns, start the system and then let it work unattended. And it can be done during the day or overnight!

It can be used either to increase throughput or, for example, to reduce the workload of laboratory staff when the number of samples is lower. A new dimension in dioxin / PCB analysis without cross contamination!

The DEXTech 16 default methods comply with all current standards such as US-EPA 8282B, 1613, 1668c, EU comission regulation (EC) No 589/214, No 1881/2006, No 152/2009, No 2002/32, GOST 34449-2018 and others.

For difficult matrices, such as room temperature curing samples, we recommend the DEXTech Heat.

More DEXTech systems, recommended columns and QS column certificates:

SYSTEM AT A GLANCE

Clean up to 15 Samples in a Sequence Unattended

Easily accessible sample loop, valves and hose connections. All elements that come into contact with the sample are already rinsed during the process and thus remain contamination-free.

For the automatic feeding and collection of 15 cleaned samples in two fractions with dioxins and PCBs. The fraction glasses can be evaporated directly and without further transfer in the D-EVA.

to EVAporationInsert up to 15 column sets in a few minutes. These are hermetically sealed by the system until they are used and thus protected against humidity. After the start of the sequence, a column set is transferred to the processing station and pressed there. After use and drying, the columns are automatically transferred back to the storage station. At the end of the sequence, the columns can be removed and a new sequence can be prepared immediately.

All functions of the system are controlled via the touch display. Recommended and tested standard methods for different objectives (e.g. dioxins and PCBs or PCBs only, etc.) are stored in the system so that no method development by the customer is required. Of course, own methods can also be implemented and stored.

Little effort - High throughput

Robust and low maintenance

DEXTech 16

Dioxin and PCB Analysis is this Simple

With the sample preparation system DEXTech 16, LCTech has developed a sensation for PCB and dioxin analysis. The fully automatic clean-up of 15 samples in 1 sequence: for food, feed, environmental and biological samples. The system separates PCBs and dioxins in one fraction each.

Processing of 15 samples in 1 sequence around the clock, day and night: Find out how it works in the product video.

Fractionation on All

DEXTech Systems

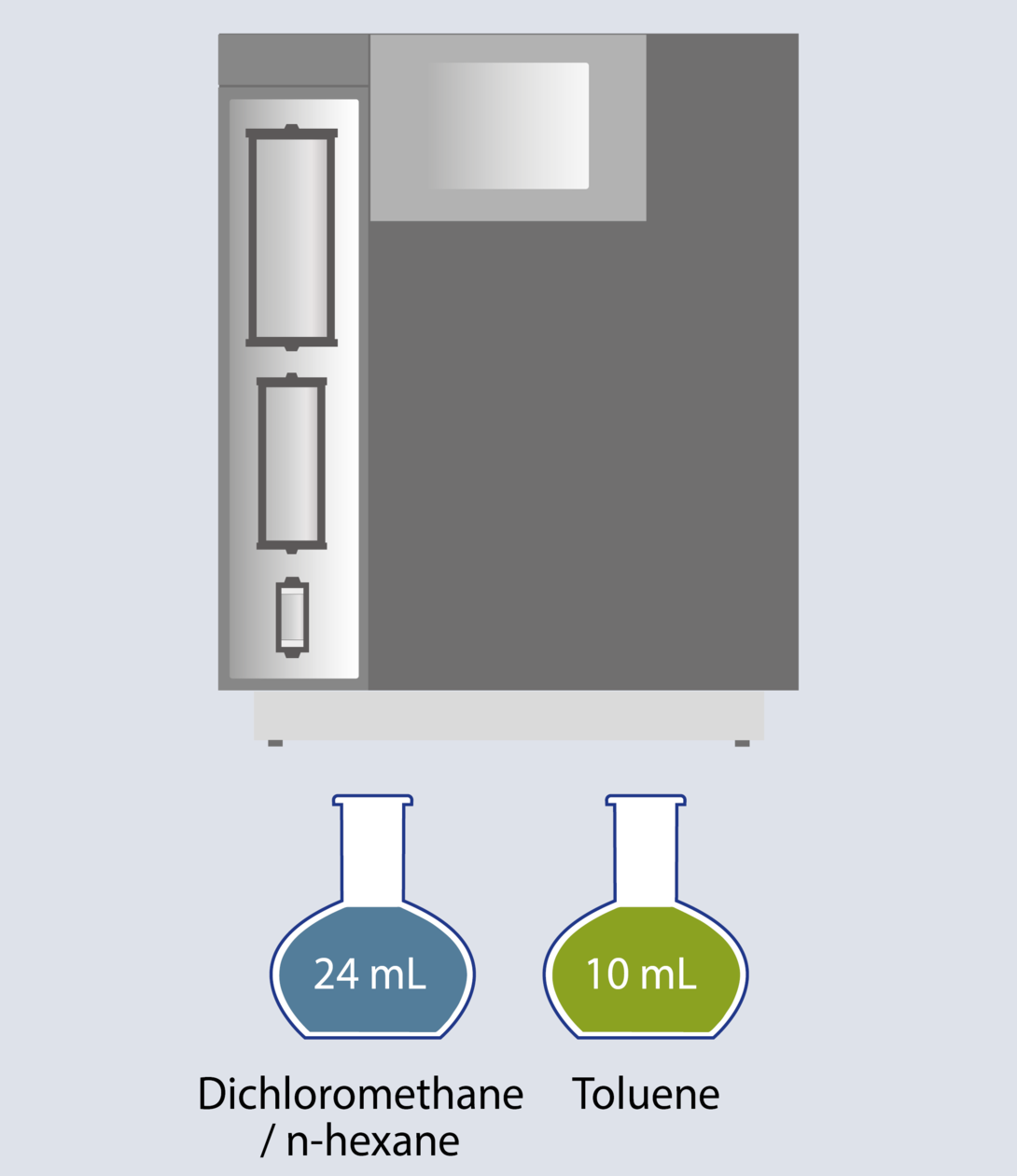

3 Columns

2 Fractions

Fraction 1 (24 mL):

Mono-ortho-PCB + ndl-PCB + PBDE

Fraction 2 (10 mL):

Non-ortho-PCB + PCDD/F + PCNs

Total process time: 65 min

Total process time SMART: 45 min

Also available as DCM Free Method!

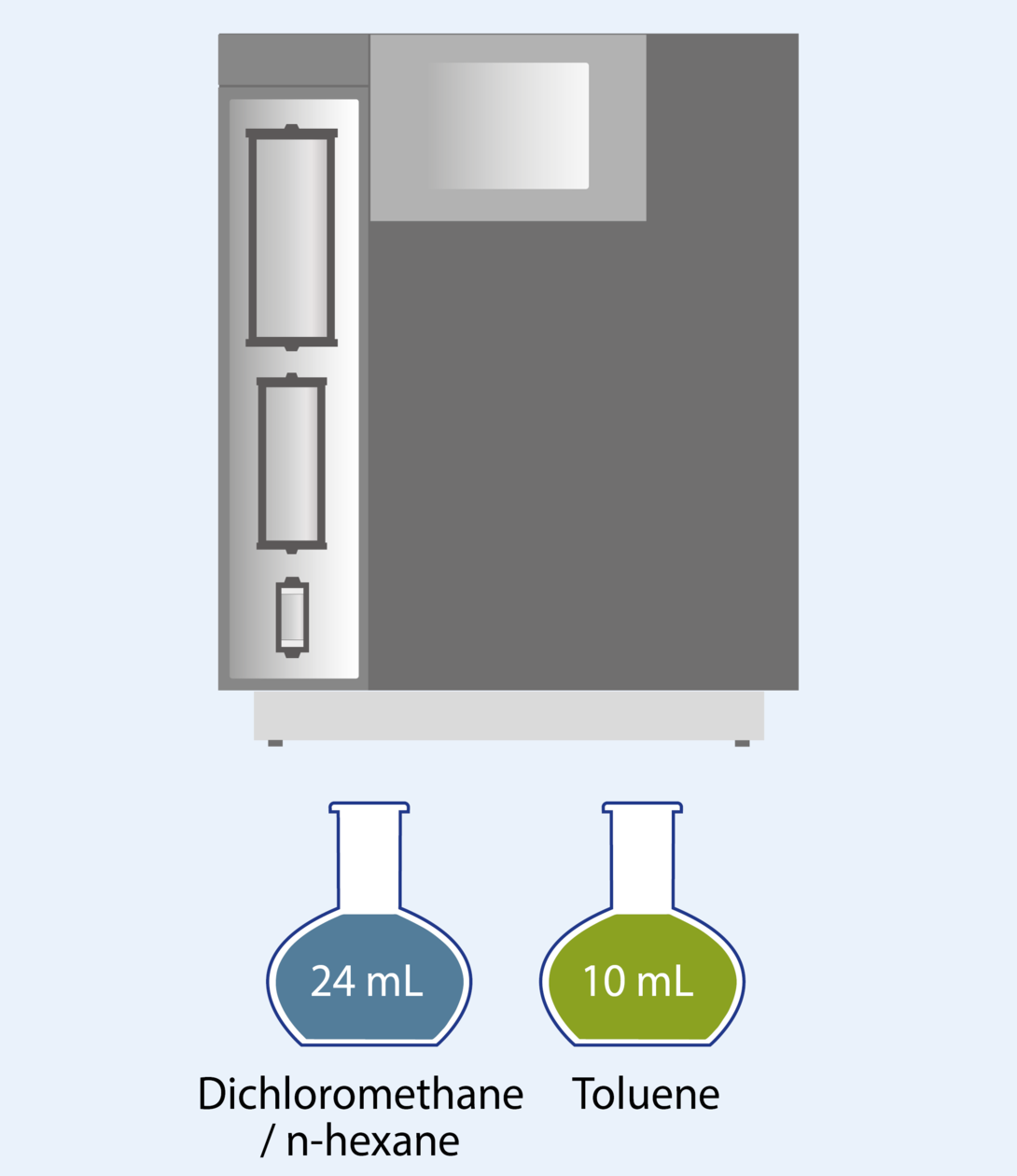

3 Columns

2 Fractions

Fraction 1 (24 mL):

Mono-ortho-PCB + ndl-PCB + Non-ortho-PCB

Fraction 2 (10 mL):

PCDD/F

PCNs

Total process time: 72 min

Total process time SMART: 52 min

Unique: All PCBs in one fraction!

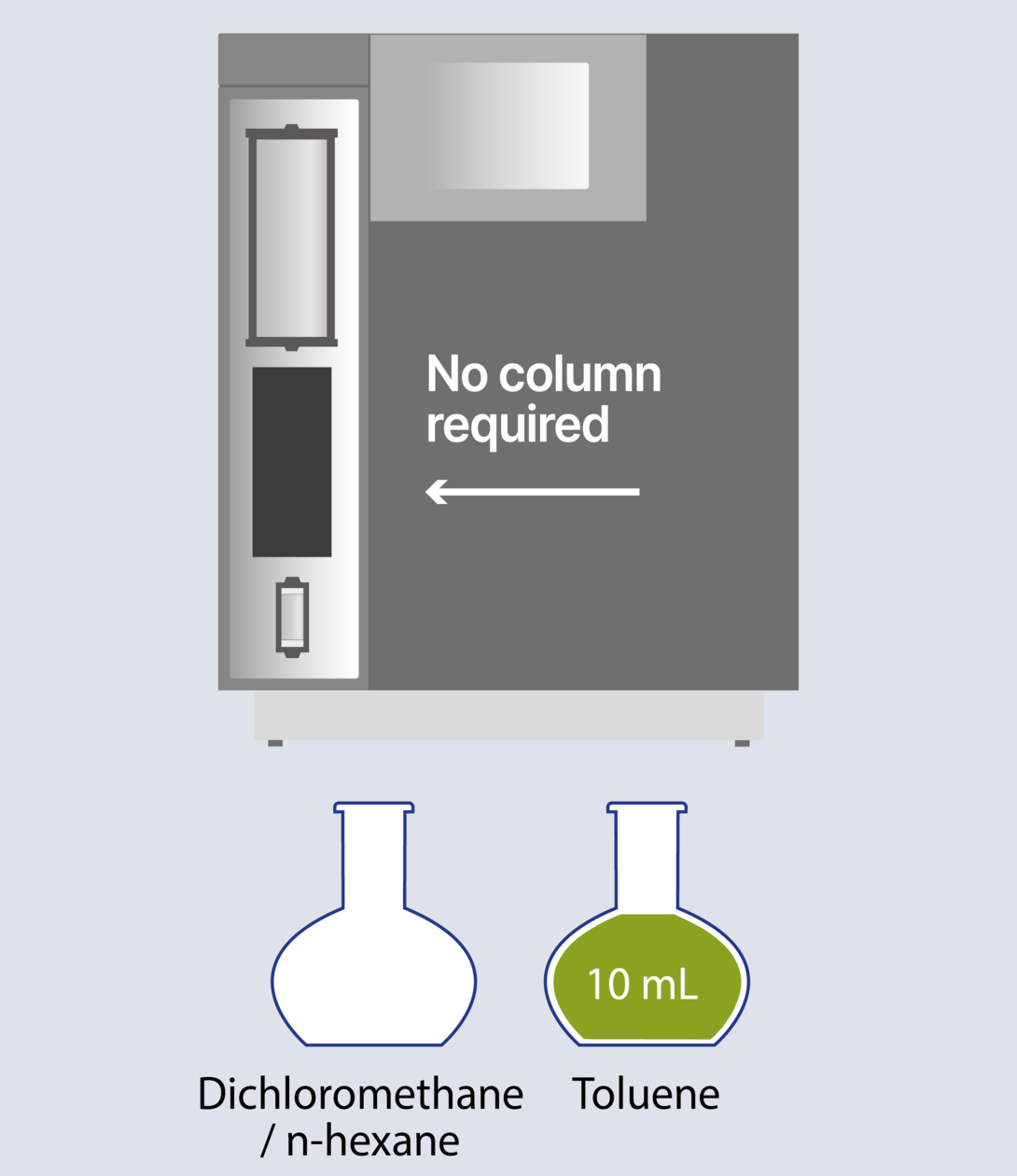

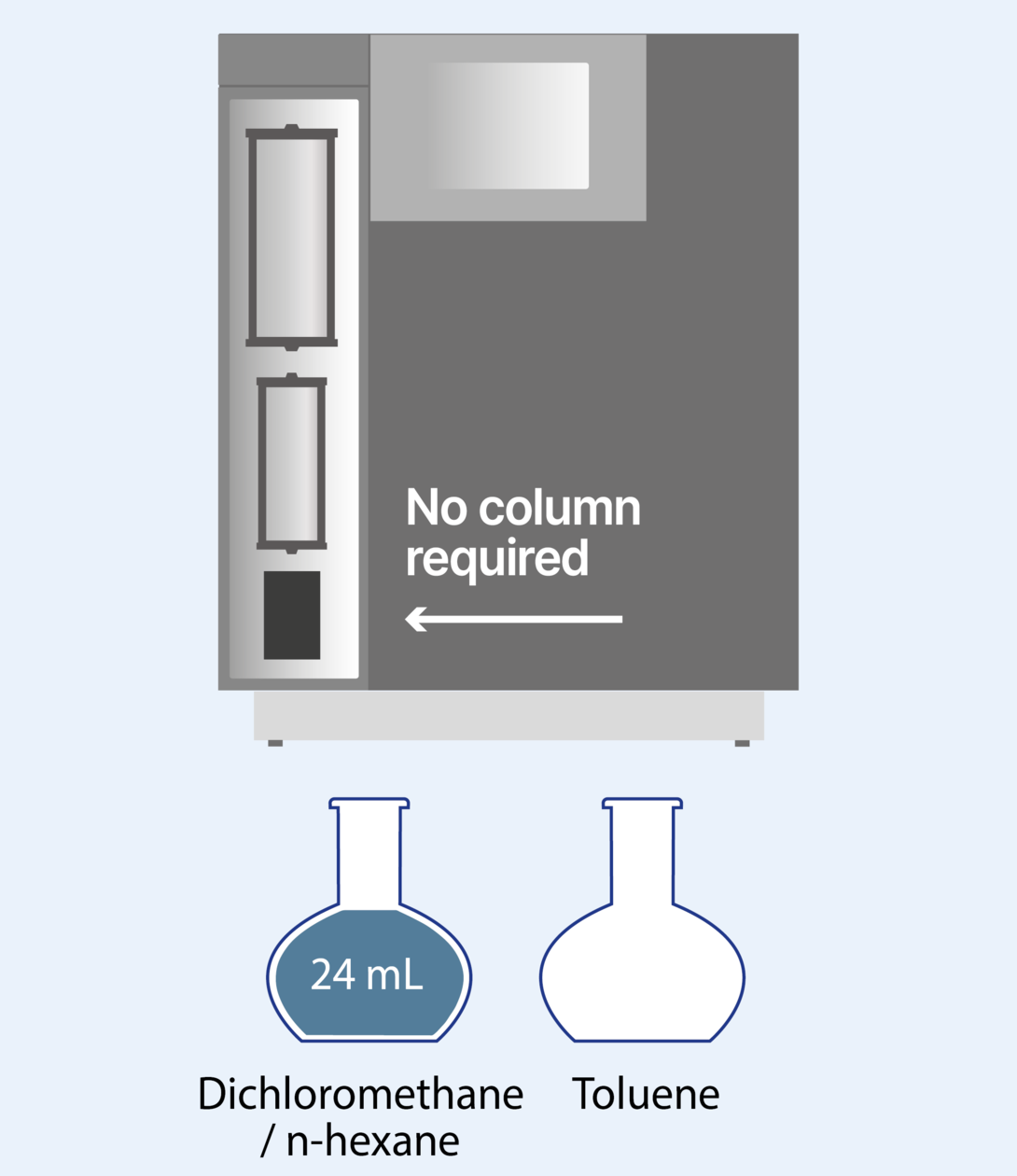

2 Columns

1 Fraction

Fraction 1 (24 mL):

-

Fraction 2 (10 mL):

PCDD/F

PCNs

Total process time: 52 min

Total process time SMART: 32 min

Cost saving and DCM Free Method!

- PCB only (Mono-ortho-PCB, + ndl-PCB, + non-ortho-PCB)

- PCB 209 (All 209 PCBs)

2 Columns

1 Fraction

Fraction 1 (24 mL):

PCB only

(Mono-ortho-PCB,

+ ndl-PCB,+ non-ortho-PCB)

Total process time: 54 min

Total process time SMART: 34 min

Fraction 1 (24 mL):

PCB 209 (All 209 PCBs)

Total process time: 33 min

More DEXTech Systems and

Recommended Columns

The basic system for daily routine. Proven hundreds of times in laboratories around the world.

Read more

The heated system so that even hardening samples remain fluid from presentation to loading and are reliably processed without clogging.

Read more

Silica-Säulen und Alox-Säulen aus Glas oder Kunststoff.

Sie haben die Wahl!